In every industrial plant, every drop counts.

Whether it’s water treatment, chemical processing, or irrigation — accurate flow measurement is the heartbeat of efficiency.

But here’s the question engineers often face:

“Should we choose an Electromagnetic Flow Meter or an Ultrasonic Flow Meter?”

Both are modern, precise, and reliable. Yet, they sense flow in entirely different ways — one feels it through magnetism, the other hears it through sound.

Let’s see how both of them measure the flow.”

Understanding Electromagnetic and Ultrasonic Flow Meters

In a busy industrial city, a water utility struggled to track water usage in its pipelines. They called in two experts — Mr. Mag (Electromagnetic Flow Meter) and Mr. Sonic (Ultrasonic Flow Meter).

Both promised accuracy, but their methods were like night and day.

So arrived two wise instruments —

Electromagnetic Flow Meter (Mag Meter) and Ultrasonic Flow Meter (Sonic Meter) — each offering their unique way of listening to the flow.

One relied on science of conductivity,

the other on sound and time.

What is an Electromagnetic Flow Meter?

Electromagnetic Flow Meters, often called Mag Meters, work on Faraday’s Law of Electromagnetic Induction.

When a conductive fluid (like water, slurry, or wastewater) passes through a magnetic field inside the meter, it generates a small voltage. The meter reads this voltage to calculate the flow rate.

Imagine it as:

“A whisper between water and magnet — a quiet conversation about speed and volume.”

Key Advantages:

- Highly accurate for conductive liquids

- Works well with dirty fluids, slurries, and wastewater

- No moving parts → low maintenance

- Ideal for industrial flow measurement, water treatment, and chemical plants

⚠️ Limitations:

- Cannot measure non-conductive fluids (like oil or pure water)

- Requires pipe contact for installation

What is an Ultrasonic Flow Meter?

Ultrasonic Flow Meters measure flow using sound waves. They send ultrasonic signals through the fluid and calculate the time difference between waves traveling with and against the flow.

It’s non-invasive, smart, and precise — almost like a stethoscope for your pipeline.

“It doesn’t touch the flow — it just listens to its rhythm.”

Key Advantages:

- Works with all types of liquids (conductive or not)

- Clamp-on type installation — no pipe cutting needed

- Perfect for temporary flow measurement, energy audits, and non-contact applications

- Suitable for large pipelines or hard-to-reach areas

⚠️ Limitations:

- Accuracy can be affected by air bubbles, suspended solids, or pipe material

- Requires precise sensor alignment

Difference Between Electromagnetic and Ultrasonic Flow Meter

Here’s a clear flow meter comparison chart for quick reference:

| Parameter | Electromagnetic Flow Meter | Ultrasonic Flow Meter |

|---|---|---|

| Working Principle | Electromagnetic Induction (Faraday’s Law) | Transit Time or Doppler Effect (Ultrasonic Waves) |

| Fluid Type | Conductive Liquids Only | All Liquids (Conductive/Non-conductive) |

| Installation Type | Inline | Inline or Clamp-on |

| Accuracy | Very High for Conductive Fluids | High but Sensitive to Air/Solids |

| Maintenance | Very Low | Low (requires calibration) |

| Best Used For | Water/Wastewater, Slurries, Industrial Process | Clean Water, Energy Audits, Temporary Measurement |

| Typical Industries | Chemical, Water, Food, Pharma | HVAC, Power, Oil & Gas, Utilities |

Which Liquid Suits Which Flow Meter?

Electromagnetic Flow Meters:

Work best with conductive liquids — industrial water, wastewater, slurry, effluents, chemicals, and groundwater.

If the liquid has minimum conductivity, a magmeter provides stable and highly accurate readings.

Ultrasonic Flow Meters:

Suitable for clean to moderately dirty liquids — drinking water, RO/DM water, chilled water, oils, fuels, and large pipeline flows.

If the liquid allows ultrasonic waves to pass smoothly, the meter performs exceptionally well.

Real-World Example: Flow Control in Mumbai

At a municipal water board in Mumbai, engineers faced two situations:

- Main pipelines — carrying large volumes of treated water — demanded high-accuracy, long-term monitoring.

- New distribution zones — where testing and calibration changed frequently — needed a portable, quick-to-install solution.

Their solution?

Electromagnetic flow meters for permanent installations, and ultrasonic flow meters for flexible, short-term measurements.

The project head joked:

“Mag meters are our heartbeat monitors, and ultrasonic ones — our stethoscopes.”

Choosing the Right Flow Meter for Your Industry

| If You Need… | Choose This Meter |

|---|---|

| Measuring conductive liquids like water, slurry, wastewater | Electromagnetic Flow Meter |

| Measuring non-conductive liquids like oil or solvents | Ultrasonic Flow Meter |

| A permanent, in-line system for 24/7 monitoring | Electromagnetic |

| A portable, non-contact meter for quick inspection | Ultrasonic |

| Highest accuracy in tough conditions | Electromagnetic |

| Minimal installation downtime | Ultrasonic |

Final Thoughts — Every Flow Has Its Own Symphony

At the end of the day, both Electromagnetic and Ultrasonic Flow Meters are masters of measurement — each with a unique rhythm.

If you’re still wondering which flow meter fits your system,

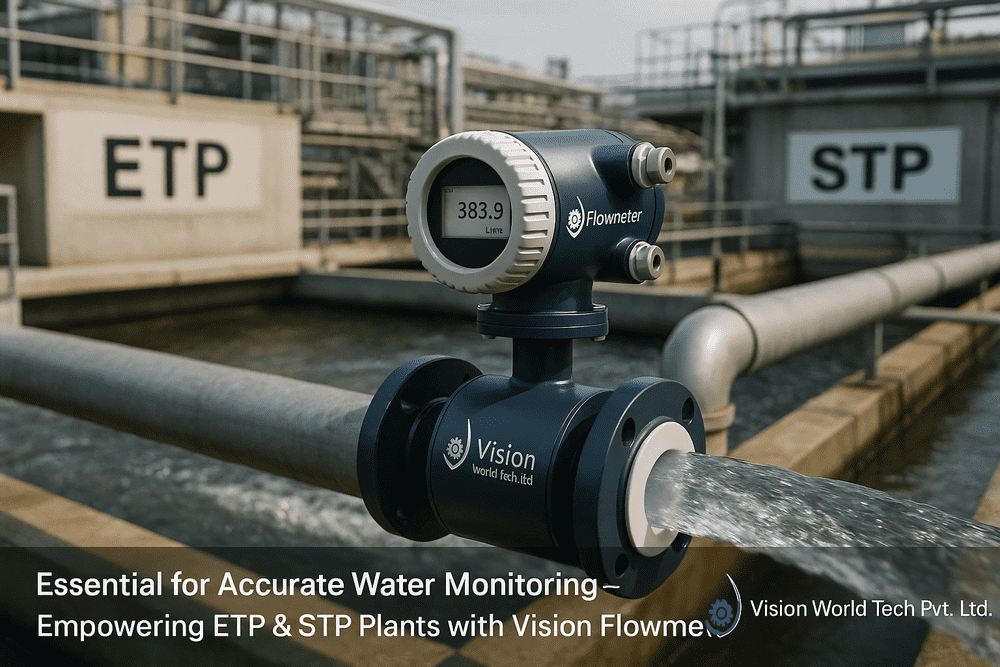

Vision World Tech Pvt. Ltd. is here to guide you.

We help industries across India design, install, and integrate smart flow measurement systems that bring clarity, compliance, and confidence to your operations.