Electromagnetic Flow Meter Installation based on CGWA norms

One of the most reliable and efficient measurement tools used in fluid measuring, the electromagnetic flow meter stands all in the application framework. Starting from water treatment plants to chemical processing facilities, hardly any industry today where this versatile instrument’s usage is not noticed in flow meter applications. Yet, knowing how such a flow meter should be installed can be both useful and intriguing. As a professional in your field, whether as an engineer who has spent years working in the field or more about to wade into the world of fluid dynamics, a well-installed device saves you precious time and resources and headaches down the line. Now, let’s dive into some of the main steps and considerations related to installing an electromagnetic flow meter with flair and precision.

What is an Electromagnetic Flow Meter?

A small rundown of an electromagnetic flow meter before the installation guide could be in order. In brief, an electromagnetic flow meter, or mag meter for short, is a device that measures the flow rate of conductive fluids via Faraday’s Law of Electromagnetic Induction. It’s basically the principle where a conductive fluid passing through a magnetic field will produce an electric signal proportional to the fluid velocity, making it possible to measure accurately the flow rate in a flow meter.

Benefits of Electromagnetic Flow Meters

Electromagnetic flow meters have quite several advantages:

- High Accuracy: Allows precise measurements of flow.

- No Moving Parts: Reduces frequent servicing and wear.

- Versatility: Suitable for various applications and fluid

- Low Drop Pressure: Little impact on the fluid flow

Pre-installation Considerations:

A good performance, whether at the theatre or a music venue, takes place in preparation. Here are the key considerations to take into account before installation:

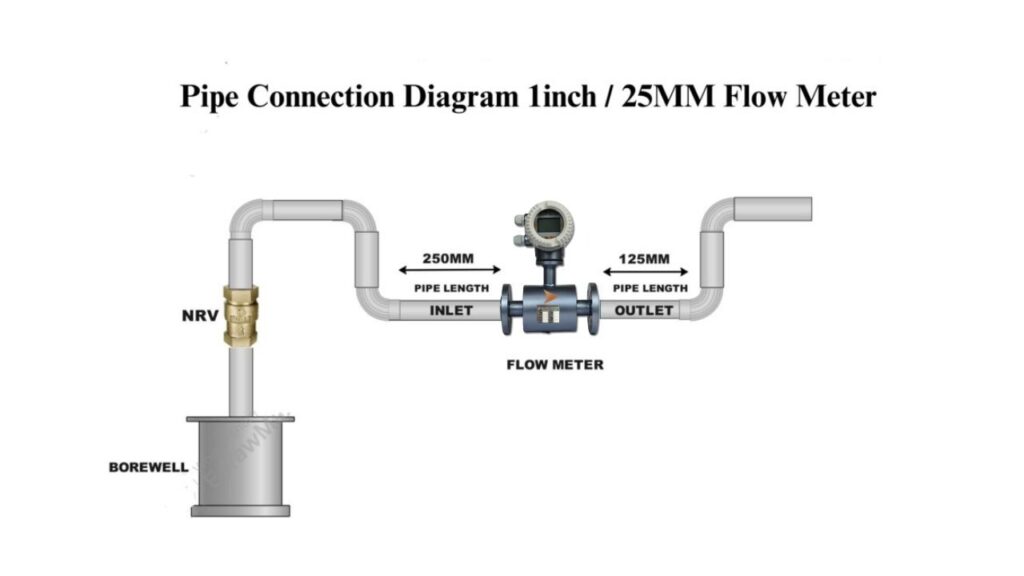

- Step Select a Desired Location: A good location for an installation can be the difference between relatively adequate accuracy of flow measurements and marginal success. Installation should occur at a point within the piping having ten pipe diameters upstream and five downstream from the flow meter that helps reduce disturbances in the flow.

- Step Interchangeability Confirm that the chosen flow meter is suitable for the fluid characteristics, for example, temperature, pressure, and chemical make-up.

- Step Power Supply and Grounding Confirm that the location meets your mag meter’s power supply specifications. Proper grounding must also be provided for safe and reliable flow measurement.

Installation Steps of Electromagnetic Flow Meters

- Installation Location

- Avoid Disturbances: Ideally, the flow meter installation must be away from sources of turbulence such as pumps, bends, valves, and other obstructions that may interfere with the normal flow pattern. Its installation should be horizontal or vertical in an upward flow through a vertical pipe rather than a horizontal pipe to prevent trapping of air bubbles and possible sedimentation that degrades the measurements taken.

- A correct installation location ensures proper measurement of flows. Straight Pipe Length: Install the flow meter at least five to ten diameters upstream and two to five diameters downstream.

- This provides straight flow that could stabilize flow and optimize measurement performance.

- Proper grounding is one of the basic requirements for ensuring there are proper measurements with minimal interference from electrical noises.

Grounding Rings: Use grounding rings, if the liquid measured is non-conductive or if the piping material is not made of metal so that proper electrical grounding takes place.

Grounding Separation: Ensure the grounding of the flow meter separately from other electrical devices so that any interference may not happen. Data can obtained safely. - Proper Alignment

The position of the flow meter can significantly influence its performance and productivity.

Electrode Positioning: Place the electrodes parallel to prevent air bubbles from interfering and causing incorrect measurements.

Flow Direction: Always align the flow direction with the arrow on the flow meter for proper functioning. - Elimination of Air Bubbles and Suspended Particles

Air bubbles and suspension particles are probable sources of error in the measurement of flows, and thus, their prevention is very essential.

Full Pipe Condition: The fluid in the pipe should always be full to prevent air pockets which provide erroneous readings.

Upward Flow: Installation in a vertical position with upward flow would enable the residence time of the fluid sediment inside the pipe be minimized . - Temperature and Pressure Requirements

Temperature and pressure variation also affects the performance of electromagnetic flow meters, therefore they need to be regulated.

Operating Range: The flow meter must operate in an environment with temperatures and pressures within stated ranges. This includes operating range conditions to ensure accuracy and reliability.

Thermal Expansion: One would not have to exclude the thermal expansion that might affect piping and flow meter. Eliminate any negative interaction that affects performance. - Maintenance and Calibration

Maintenance should always be routine to make the flow meter last and maintain its accuracy.

Cleaning: De-foam the electrodes at regular intervals in case there are chances of any accumulation or fouling which would interfere with the accuracy of measurements.

After installation:

After installing, final few steps check everything is working as expected

- Calibration and Test: Carry out preliminary tests and calibrate the flow meter to get an assurance of its correctness. Calibrating periodically means that the measuring meter will remain precise as time progresses.

- Observation and Maintenance: Schedule regular checks and clean the flow meter to monitor wear that affects performance.

- Logging: data from your flow meter reveals insights about system performance, helping you detect problems before they escalate.

Conclusion

Proper installation of the electromagnetic flow meters ensures that the right and accurate measurement of fluid flow is taken. Based on these considerations, flow meters will have optimal performance, long life, and sufficient maintainability for industrial engineers, maintenance technicians, plant managers, and other water management companies. For additional information or customized options, just contact our experts.

Call-to-Action: Ready to learn more about optimizing your flow meter installations? Schedule a consultation with our team today!

By following these guidelines, you ensure optimal performance and reliability of electromagnetic flow meters for accurate, consistent measurements.

To learn even more best practices and helpful guidance, sign up for our newsletter or contact our support team.