What is an Digital Electromagnetic Flow Meters ?

Electromagnetic Flow Meters also called Mag flow meter or Digital Water flow meter basically it’s works on Faraday’s Law of Electromagnetic Induction which measures the flow rate of conductive fluids. This Water flow meter are one of the most reliable and accurate flow measurement devices used in various industries like in Water & Wastewater Treatment industry, Chemical industry, Power Plants/ Power Generation industry, Food Service Industry, Cement Manufacturing Industry , Mining and Mineral Processing industry etc.

Industries That Uses Digital Electromagnetic Flow Meters:

1. Water & Wastewater Treatment industry :

Water & Wastewater Treatment industry is primary sector where water flow meter provide accurate flow rate measurements, they have no moving parts, require low maintenance, durable, and handle liquids with solids or ore slurry.

Uses of Flow meter in Water & Wastewater Treatment industry :

Municipal Water Supply

- Track water consumption.

- Ensure proper billing.

Wastewater Treatment Plants

- Inflow and outflow of sewage water.

- Sludge and slurry movement.

- Treated water discharge for compliance.

Groundwater Extraction Monitoring

- Monitor groundwater Extraction.

- Prevent over-extraction.

- Report usage data to authorities.

2. Chemical Industry:

In Chemical industry mag flow meter provide accurate monitoring of Acid, Alkali, solid and chemical by-products by using telemetry system get real-time monitoring for environment safety flow meter are very essential tool.

Uses of Flow meter in Chemical Industry:

Waste Chemical Management

- Monitors flow of Slurry-Type Chemicals and by-products.

- Ensures environmental safety.

Acid and Alkali particals Measurement

- Accurate flow monitoring of hydrochloric acid, sulfuric acid, caustic soda, etc.

- Flow measurement for high-value or sensitive chemicals.

- Telemetry-enabled for real-time flow monitoring.

3. Food and Beverage Industry:

Electromagnetic flow meters are used in the food and beverage industry for measuring liquid flow accurately. They work without moving parts, reducing maintenance needs and ensuring hygienic operation. These flow meters handle a variety of liquids, such as juices, dairy products, and water, without being affected by temperature, pressure, or viscosity changes.

Uses of Flow meter in Food and Beverage Industry:

Beverage Production (Juices, Soft Drinks, Alcohol)

- Flow monitoring during mixing, bottling, and transfer.

- Ensures precise blending and ingredients.

Milk and Dairy Processing

- Accurate measurement of milk flow in packaging.

- Handles thick dairy products like cream.

Built for Hygiene and Performance

- Compliance with food safety standards.

- Sanitary process connections.

4. Power Plants and the Power Generation Industry:

flow meters play a important role in power plants and power generation industries. These devices measure the flow rate of electrically conductive fluids. They are commonly used to monitor and control water usage in boilers, cooling systems, and other critical processes. Their non-intrusive design reduces maintenance needs and ensures reliable operation, even in harsh conditions.

Uses of Flow meter in Food and Beverage Industry:

Cooling Water Systems

- Measures flow in cooling loops and heat exchangers.

- Helps optimize heat removal and maintain efficiency.

Chemical Dosing & Water Treatment

- Accurately controls treatment chemicals.

- Supports pH balancing systems.

CGWA Guidelines for Electromagnetic Flow Meters

Mandatory Installation of EMFMs with Telemetry

All industries extracting groundwater must install calibrated Electromagnetic Flow Meters with telemetry systems to record and transmit usage data to CGWA servers in real-time.

1. Industries Required to use Flow meter

- Water & Wastewater Treatment Plants.

- Power Generation Units.

- Food and Beverage Manufacturers.

- Chemical and Petrochemical Industries.

- Mining, Textile, Paper, and other groundwater-intensive sectors.

2. Third-Party Calibration

Flow meters must be calibrated by NABL-accredited labs or authorized agencies to ensure accuracy and compliance.

3. Online Monitoring Systems

The telemetry device must automatically transmit groundwater extraction data to the CGWA online portal.

4. Annual Reports and Audits

Industries are required to maintain digital logs and submit water extraction records to regional groundwater authorities during audits.

5. Non-Compliance Penalties

Failure to install or operate EMFMs as per CGWA norms may lead to:

- License suspension.

- Heavy penalties.

- Closure notices under environmental laws.

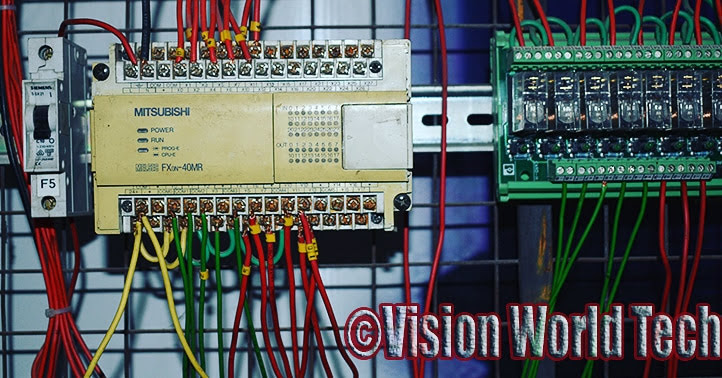

Why choose Vision World Tech Pvt Ltd for Digital Flow Meter installation?

At Vision World Tech Pvt Ltd, we manufacture and supply Electromagnetic Flow Meters with integrated telemetry that meet all CGWA and HWRA compliance requirements.

Our flow meters come with:

- NABL-certified calibration certificates.

- Real-time telemetry integration.

- Secure data transfer to CGWA servers.

- Installation, training, and annual maintenance support.

- Easy to integrate with existing SCADA and telemetry systems.

- 1-year full replacement guarantee expect physical damage.