Introduction

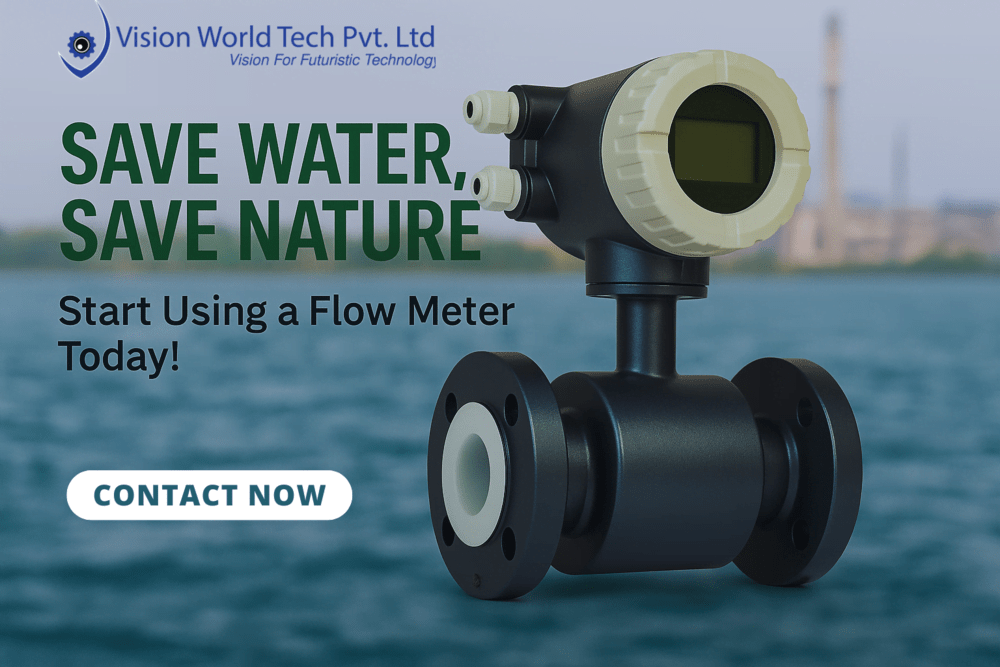

Among the various flow measurement techniques available, electromagnetic flow meter have emerged as a dependable and widely adopted solution. So, what a flow meter is. It is a device that measures the flow rate of conductive fluids, such as water or chemicals.

Faraday’s law ensures accurate measurements, regardless of the fluid’s temperature, pressure, or viscosity. because flow meter have gained popularity for their versatility and reliability in a wide range of industrial applications.

Evolution of magnetic Flow Meter

The key advantage of mag flow meter is their non-intrusive nature. Mechanical flow meters that require insertion into the flow path and flow meters can be installed externally, eliminating the risk of clogging or pressure drop. For example, this feature reduces maintenance efforts and ensures uninterrupted operations, minimizing downtime and maximizing productivity.

In terms of practical applications, magnetic flow meters find wide usage across various industries. So, in water treatment plants, they accurately measure the flow of both raw water and treated water, aiding in efficient distribution and ensuring compliance with water quality standards. In chemical processing plants, these meters play a crucial role in monitoring the flow of chemicals, enabling precise dosing and minimizing waste. Similarly, in the oil and gas industry, electromagnetic flow meters are utilized for measuring the flow of crude oil, refined petroleum products, and various chemicals, helping optimize production processes and ensuring accurate billing.

Key Components of Electromagnetic Flow Meter

The key components of water flow meters include the flow tube, electrodes, and transmitter. The flow tube is where the fluid flows, while the electrodes measure the voltage generated. Because the transmitter processes the voltage signal and calculates the flow rate. In Rajasthan We are leading manufacturer and supplier, of electromagnetic flow meters as per CGWA guidelines. Offering the best services and maintenance at affordable prices.

Best Practices –

Proper Sizing and Calibration

Ensuring the correct sizing and calibration of electromagnetic flow meters is essential for accurate measurements and compliance with industry standards.

Integration with SCADA Systems

Integrating flow meters with Supervisory Control and Data Acquisition (SCADA) systems allows for remote monitoring, data collection, and real-time decision-making.

Training and Education for Operators

Providing proper training and education to operators on the installation, calibration, but maintenance of electromagnetic flow meters is crucial for optimal performance and compliance.

Conclusion

Electromagnetic flow meters have become an indispensable tool for industries seeking accurate flow measurement solutions while complying with governmental regulations. but their non-intrusive nature, high accuracy, and wide range of practical applications make them an ideal choice for various industries. By investing in reliable flow measurement technology, industries can optimize their processes, minimize waste, and contribute to a sustainable future.

Remember, when it comes to flow measurement, accuracy, and compliance go hand in hand. Embrace the power of electromagnetic flow meter and unlock their potential to drive efficiency and productivity in your industry.

For more information or assistance with MAG flow meter solutions, feel free to contact us at Vision World Tech Private Limited in Jaipur, Rajasthan via 8505000822 or www.visionworldtech.com We are here to help you make informed decisions and ensure seamless operations.

Stay compliant, stay efficient, and stay ahead with us!

Thank you