what is PLC Programming?

PLC programming is similar to brain programming. Like our brain respond to the outer actions based on inner knowledge. Similarly, In PLC programming we feed or insert some coding and programs in the software and it responds accordingly. Hence, for best PLC Programming at Rajasthan do contact Vision World Tech Pvt Ltd

Programming a PLC is the most important aspect of industrial automation. By learning how to program a PLC, one can effectively do the industrial process. Here will memorize the programming in PLC.

How to do PLC programming in 7 simple steps :

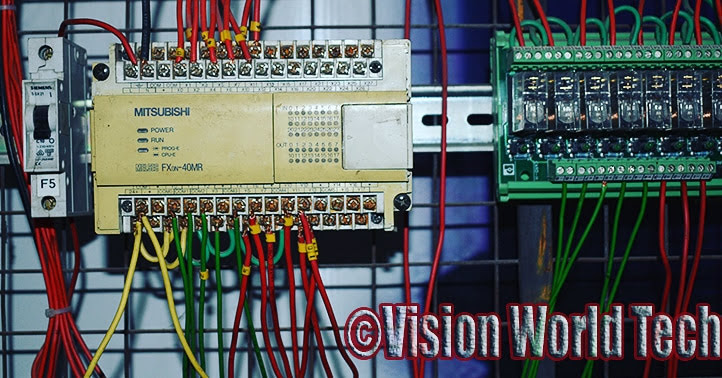

Step1: Discovering a wiring diagram.

Firstly, and the most effective step of programming a PLC is to wire it correctly. For identifying, the use of PLC. It is essential to find a wiring diagram and to understand the contradiction and position of each input and output. Every individual PLC model may have different inputs and outputs. So, first, identify the inputs and outputs carefully. Now attach the PLC to an industry-standard DIN rail system. Any single incorrect wiring can cause a catastrophic failure and may damage the PLC. So, be extremely careful and contact us for PLC Programming at Rajasthan.

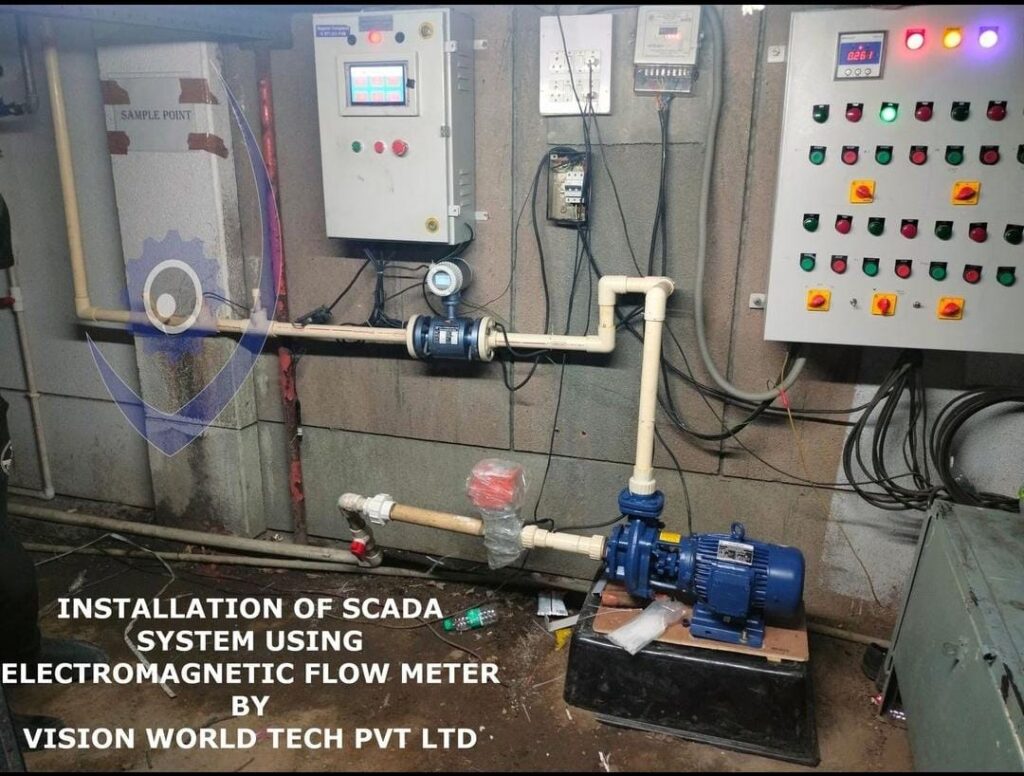

Step 2: Wiring

The second important step is the wiring. After identifying the PLC prototype, we will start wiring in genuine. For wiring first, imply input by ‘X’ and outputs with ‘Y’. Before starting wiring, check all the safety measures. We will start wiring by checking the power supply of PLC that is mentioned at the top of the L and N terminals of PLC. Afterward, connect power supply on L and N terminals of PLC. Now connect NO and NC buttons with SLBS.

Step 3: Install Programs

Thirdly, we will do program installation. That is installing the correct software for the programming in PLC. Ask a local executive, IT specialist, or director to install the files and all necessary serial numbers and product keys. After completing the setup of all necessary programs. Make sure to restart the device to secure a finalized install.

Step 4: Networking

Fourthly, we will move towards networking. Networking is a communication of PLC and PC. For networking a PLC. First, assign an IP under networking. For example, IP 179.79.7.9. Now compose the PLCs address and connect it to the programming device using ethernet and selected properties. Left-click on _ and select properties. Check the IP address and use the IP address registered on the PLC. However, change the final number. An example IP is 179.79.7.8. After inputting the IP into the programming device press, OK and close all windows. (Add if needed)

Step 5: Programming

Fifthly, the most important aspect is programming. After activating a PLC. The very first step is to upload the program to the programming device, already present in PLC. This ensures, no valuable programs are lost from the PLC and are forced to be rewritten. To do this, first, click on the dropdown card next to the word “comms” now again, select upload. The PLC will begin uploading automatically and will present the currently installed program. After uploading, be sure to save the program. Finally, program the PLC using a background understanding of ladder logic, schematic diagrams of the projects to be programmed, and debug features that enable the program to be tested preemptively for errors. Once all errors have been rectified download the program to the PLC.

Step 6: Wiring outputs

Sixthly, we will do output wiring. For output wiring, first shut down the PLC breaker after the completion of programming. It is pivotal to cross-check the programming of PLC before wiring output. The output should be wired using the very same DIN rail and terminal blocks.

Step 7: Conclusion

This guide has provided step-by-step instructions on programming a PLC. One must be equipped with knowledge and understanding of programming. This guide is a short description of how to do programming in PLC.