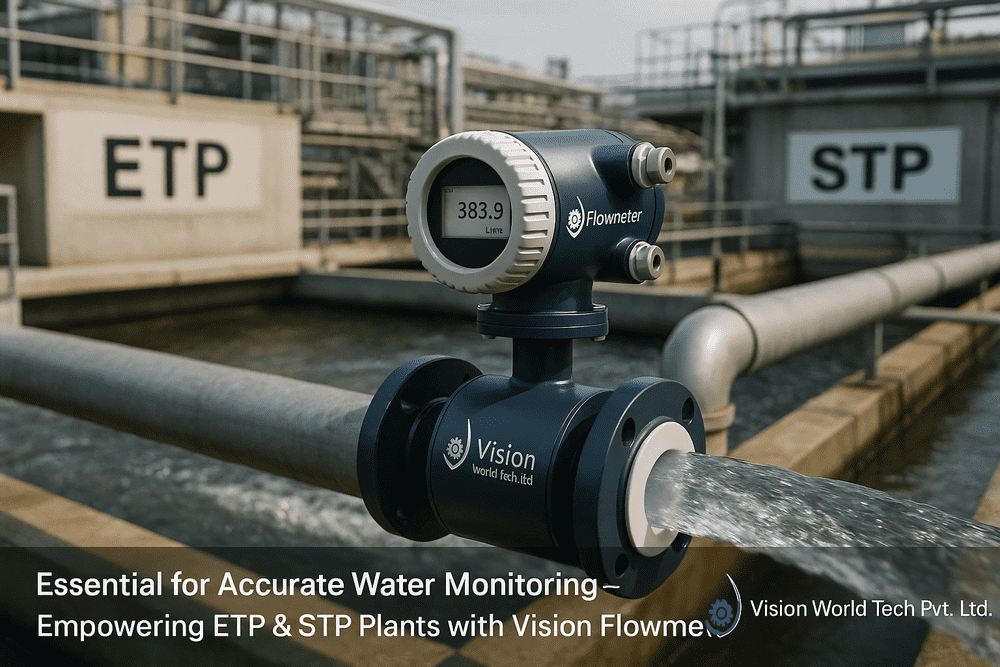

Let’s face it, when dealing with wastewater or sewage, you need to know the exact amount of water you are dealing with. If you operate anEffluent Treatment Plant (ETP) or a municipal Sewage Treatment Plant (STP), you can’t just guess the flow and hope for the best.

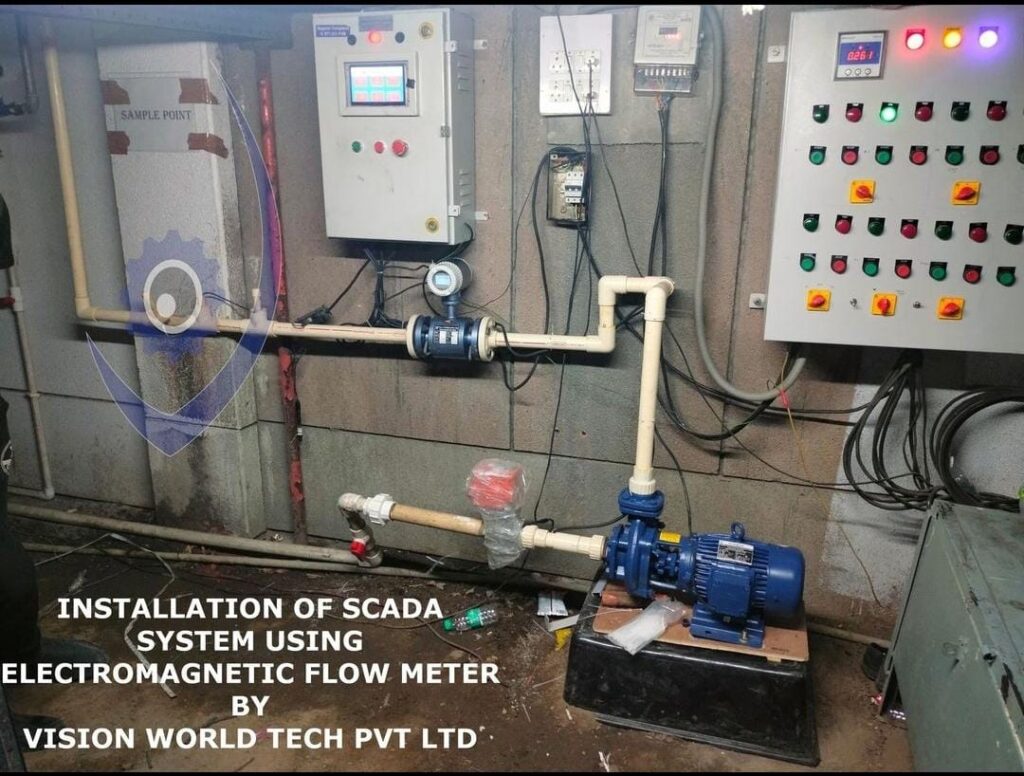

This is where electromagnetic flowmeters come in.

These aren’t random devices attached to your pipes; these are key tools to help you monitor, manage, and most importantly, comply with the “CGWA” regulations from pollution control to groundwater extraction.

Before we get into the “how,” let’s talk about the “why”.

1. You Can’t Manage What You Don’t Measure

Imagine your ETP or STP as a kitchen. When you cook a meal, you need to know the exact amount of each ingredient to make it perfect.

Now, imagine running a kitchen without knowing how much raw material you are using or how much food you are serving. It would be chaos, right?

The same principle applies to wastewater treatment.

- Inflow shows the amount of wastewater entering the system.

- Outflow indicates the volume of clean water exiting.

Electromagnetic flowmeters play a key role in maintaining control, boosting efficiency, and ensuring safety.

2. It’s Not Just Useful. It’s the Law

Many plant operators still think flowmeters are optional. But here’s the truth: they are mandatory.

Regulatory bodies like the CGWA (Central Ground Water Authority) and the RSPCB (Rajasthan State Pollution Control Board) have made it clear that digital flowmeters, often equipped with telemetry, are essential for industries that withdraw or discharge water.

This is not just a box to tick. If your plant doesn’t have a flowmeter that records and transmits data, you may face legal consequences, heavy fines, or even have your plant shut down.

So it’s not just about running your plant, it’s about being on the right side of the law.

3. Save Costs with Electromagnetic Flowmeters in ETP & STP

Here’s what most people miss: a flowmeter doesn’t just give you numbers. It helps you save money, chemicals, and maintenance time.

With the right flowmeter, you can:

- Detect abnormal flow or leakages early

- Avoid chemical overdosing (which is common and costly)

- Get cloud-based alerts and daily flow logs

This is especially valuable for plants located in places where both water and regulatory scrutiny are intense.

4. EM Flowmeters Outperform in Harsh Conditions

Let’s be real. Wastewater isn’t clean; it’s full of gunk, grease, solids, and chemicals. Most traditional mechanical flowmeters can’t handle that. They jam, wear out, or simply stop working after a few months.

But electromagnetic flowmeters have no moving parts, have no worries of pressure drop, no direct contact with flow media, and also have a long lifespan even in harsh conditions.

They’re designed specifically for dirty jobs like ETPs and STPs, and that’s what makes them worth every rupee.

Final Thoughts

If you are operating an ETP or STP and debating whether you should install an electromagnetic flowmeter, you are already late. It’s necessary because of:

- Regulatory compliance

- Reduction in unnecessary spending

- Operational cost savings

- Enhanced plant operational efficiency

- Improved efficiency in responsible water usage

Don’t consider flowmeters as an afterthought. If you are operating in any water-stressed area, dealing with a knowledgeable local flowmeter manufacturer who understands state-specific requirements (CGWA, telemetry, etc.) is advisable.