“Before understanding the concept behind the VFD in Textile Industry, we first have to understand the Textile based Machinery system.”

What is jigger Dyeing Machine and how it works?

Jigger Dyeing Machine is one of the oldest and traditional dyeing methods used for dyeing cloth. Jigger machine is suitable for dyeing woven fabrics.

In Jigger Dyeing Machine we have two main rollers which revolve on smooth bearings. In this example, we are using a 2 HP motor. So the Jigger will be attached to a 2HP motor and on a 2HP motor, we will install a 3HP drive so we can take a margin of 1HP. The fabric is wound on one of the main rollers and fed from the other. The fabric moves from one roller to the other through the dye liquor trough located at the lower part of the machine. There are various arrangements of guide rollers at the bottom of the liquor trough and during each passage, the cloth passes around these guide rollers. but during rotation of rollers, this dye infiltrates and diffuses into the fabric. The real dyeing takes place on the roller, not in the dyeing liquor. Because, only a very small length of fabric is in the dye bath and the major part is on the roller and hence, the speed of cloth during immersion in dye liquor has a very little effect on the percentage of shade produced.

Some critical problems which can be solved by using VFD in Textile Industry

- Colour variations from side to center.

- Temperature control from side to side and end to end of the roll.

- Speed control from end to end.

- Unwanted creases formation.

- Prevention of air.

Industrial VFD for Jigger & Dyeing

In the above video, we at Vision World Tech have displayed the whole functionality of VFD Drive on a Jigger Machine or Dyeing Machine. Because drive plays a key role in the Jigger or Dyeing machine. Now here will learn the working of Industrial Drive.

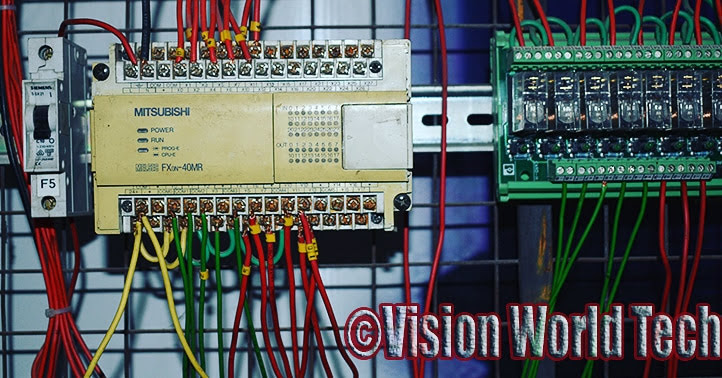

1) Variable Frequency Drive (VFD) Panel – Drive Panel is a small steel enclosed body in which the Variable Frequency Drive is fitted inside. In front of the Drive Panel, the RPM meter reflects which shows the RPM of our Motor. At the top of this RPM meter, three indicator buttons are bulging out which indicates the 3 Phase (RYB) of all three faces.

2) INVT Drive: And in this video, we are taking the INVT drive of the CHF model. In this drive, we have given an option for remote controlling. We have selected all the elements according to the drive and hence, the working also depends on it. Thus, the drive is moving at its full speed in this video that is 50 Hz.

3) Fault Reset: For fault reset we have created an external option that is a bell button. As sometimes in drive, a fault may occur due to any reason in that case the bell button plays an important role to reset the fault. Because We have to just press the bell button once and automatically it will reset the fault in VFD Drive.

Benefits Of using VFD In Textile Industry

- Energy Saving: To save energy we should use VFD Drives. example 10% less RPM for motor decrease 23% less consumption

- It controls the excess flow of electricity.

- For better process control and regulations.

- To increase or decrease the process of a machine from zero to the highest RPM.

- Provide filtrate power for power factor correction.

- Emergency bypass capability.

- It protects against overload currents.

- Safe acceleration.